Keyhole pores reduction in laser powder bed fusion additive

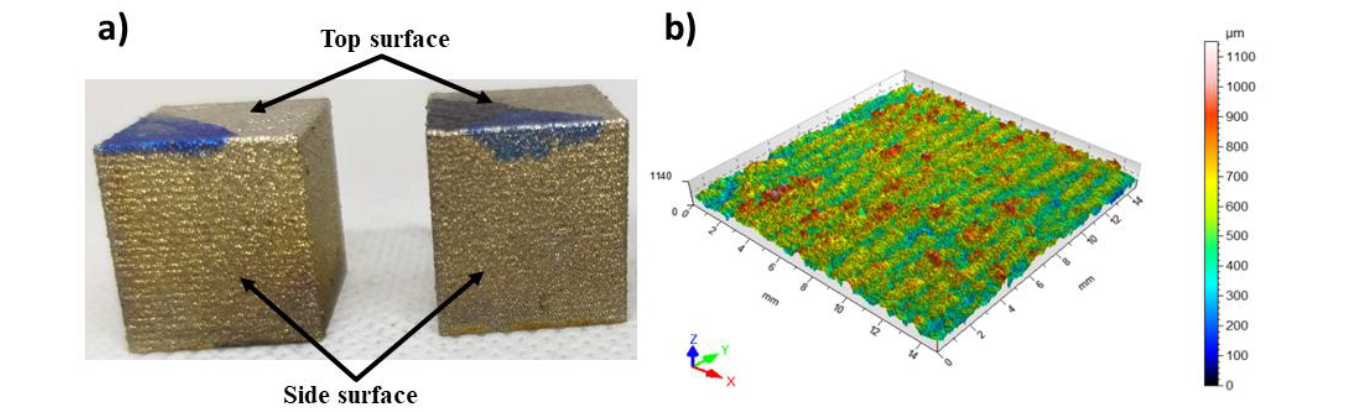

Effect of powder size and processing parameters on surface, density and mechanical properties of 316L elaborated by Laser Powder Bed Fusion – ESAFORM 2021

Micromachines, Free Full-Text

Multisensor fusion-based digital twin for localized quality prediction in robotic laser-directed energy deposition - ScienceDirect

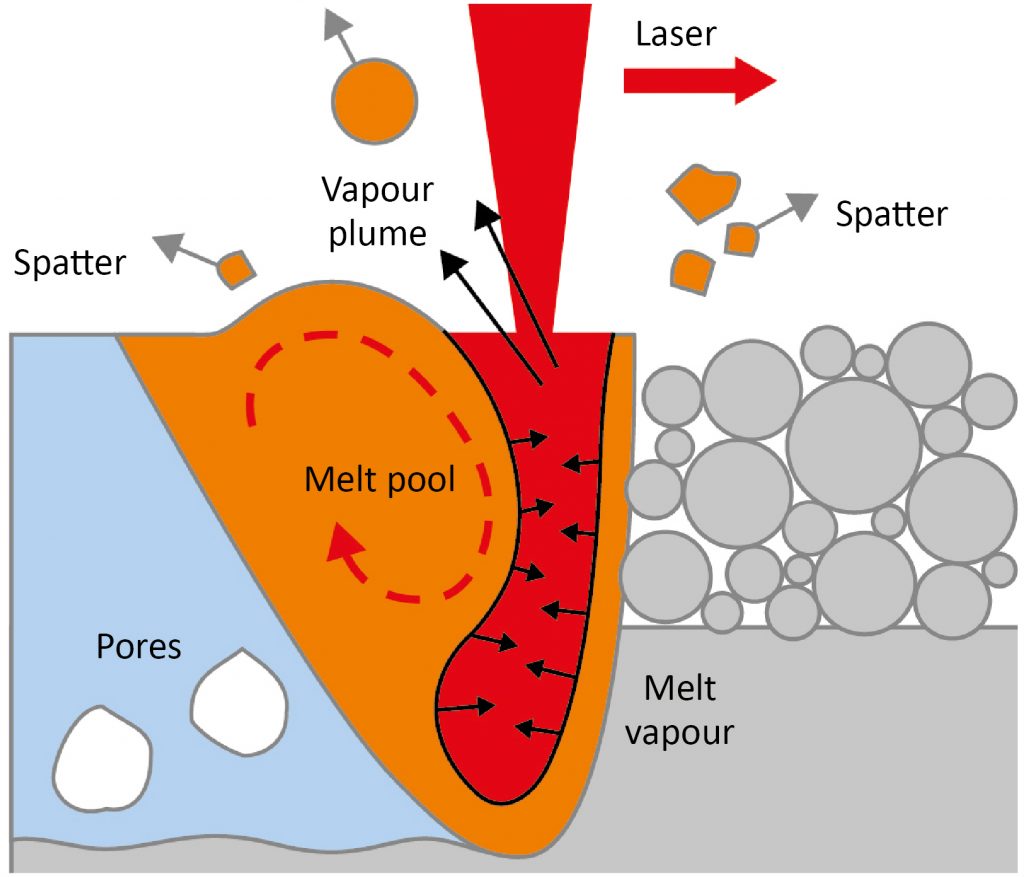

Formation of hydrogen-induced, keyhole, and lack-of-fusion pores during

Keyhole-induced porosities in Laser-based Powder Bed Fusion (L-PBF) of Ti6Al4V: High-fidelity modelling and experimental validation - ScienceDirect

A route for avoiding defects during additive manufacturing

Micromachines, Free Full-Text

Ho YEUNG, PhD

Deep transfer learning of additive manufacturing mechanisms across materials in metal-based laser powder bed fusion

M. DONMEZ, National Institute of Standards and Technology, NIST, Intelligent Systems Division

Applsci 11 12053, PDF, Heat Transfer

Ho YEUNG, PhD

How process parameters drive successful metal AM part production